and I will try to answer them.

The Main

VI allows the user to set up the initial settings for the Wunderbot's

operation. There is a cirular switch to choose between JAUS,

Manual and Autonomous Mode. We have also included switches

to choose the GPS Course or Qualification/Obstacle Course in

Autonomous Mode or to use the Keyboard or Remote in Manual Mode.

The Speed Slider allows the user to select the speed in

manual mode. On the right hand side, the variables and output

of the PID controller are shown as well as a graph of the motor

response.

This is the manual control tab of the FrontPanel. This tab is

used when controlling the Wunderbot manually with either the keyboard

or the remote control. There are keys for the desired

direction of travel and slider indicators to show he target speed for

each drive wheel.

This is the GPS Tab showing the relevant information while navigating

the GPS course. There are various LEDs indicating bolean

variables and indicators showing current location. The

boolean LEDs are invaluable for debugging purposes allowing you to see

which variables are beeing set true and therefore which sequences are

being entered.

This is showing the manual grabber subtab of the GPS tab.

This manual grab allows the user to grab different GPS points

manually to set up a test GPS navigation course.

Thsis shows the from file subtab of the GPS tab. This allows

the user to load a file of predefined GPS points to navigate.

At competition the gps course is entered into the path

planning program and the ideal sequences is determined. This

sequence is then stored in a file and loaded to the Wunderbot for the

navigation course.

This is the Obstacle tab of the front panel. This allows the

user to set constants like turning aggressivness, lookahead distance,

backup proximity etc. It also displays pertinent information

from different decisions made in the code.

Variables - GLOBAL

All of the variables for the Wunderbot are Global so they can easily be

passed between different VIs in the control loop.

These are all the uninitilized variables used by he Wunderbot.

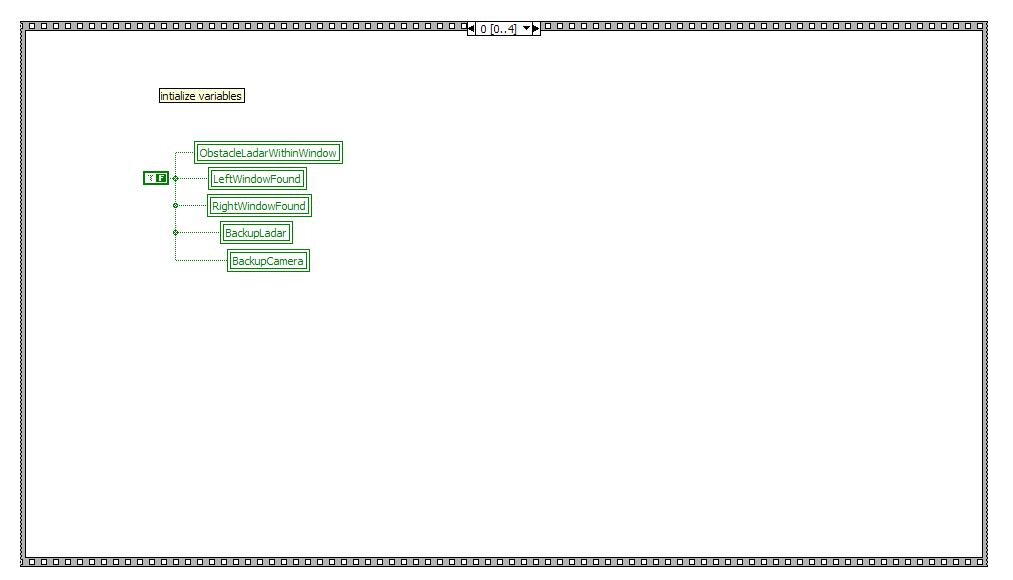

These are the initialized variables for the Wunderbot. As you

can see, this initializes some boolean variables to false and "primes

the pump" for some other systems to begin the control loop.

PID Controller - Closed

Loop Control

The Wunderbot used a PID (Proportional, Integral, Differential)

controller for closed loop control of the drive motors. This

allows the Wunderbot to compensate automatically for drive wheel

slipping or caster slipping.

This shows the initialization and setup of the PID controller.

It is bringing in the current positions and incrementing the

closed loop counter. These values are then fed into a

sequence block that goes throught the steps of PID control.

Many of the Wunderbot systems utilize sequences to simplify the overall

flow of the control algorithm. This shows the first case of

the PID controller sequence. This case takes the current and

previous positions to get a delta for use in the next case of the

sequence. It also determines the rpm of each wheel using math

logic blocks.

This case of the sequence feeds the PID constants into the PID subVI in

addition to the RPM and calculated adjustment for each wheel.

There is also a delay set to allow for the calcualtions using

current and previous positions. This feeds the output

positions through the sequence for use as feedback.

This case takes the adjustment for each wheel and applys it to the

current input for each wheel. This then does some

logic to determine if we have found a bearing or if the input to the

motor is less than 5. If either of these are true,

zeros are fed to the motor subVI. Otherwise, the adjusted

value is fed to the motor subVI.

The Main Loop

This shows the setup of the main loop

setting the delay, calculating runtime and selecting modes.

Also this shows the JAUS setup, If JAUS is selected the JAUS

case is executed.

Manual Control

This is the Manual Control Case with the remote switch off.

This maps the up, down, left, and right keys to set target

speeds for the desired directions.

This is the manual control VI using the remote control. This

feeds the set speed into the remote control subVI which outputs the

target speeds for the left and right wheels. There is also a

coded emergency stop as well. If the estop is on then the

logic forces a desired speed of zero to stop the robot.

GPS Navigation

This shows the basic flow diagram for the GPS Navigation course.

This is quite similar to the obstacle course that will be

discussed below, except that the GPS takes the GPS bearing into account

while the obstacle course sequence checks the LADAR and Vision and

makes a decsison based on both sets of data.

This sequence case initializes any variables using the GPSCalc subVI

as well as initializes some boolean variables to false.

This second case checks to see if the load file boolean variable is

true. If it is, it loads the next GPS point. If not it checks

to see if we have found our goal, if we haven't, it continues through

the loop.

The third case of the sequence checks the distance to the next goal GPS

point, It then determines if we are witthin the expected

radius of the GPS point. If so we set FoundGoal to true. It

then does logic to determine whether or not to make a LadarMove.

In the fourth case we check if we have found the goal or are in a

LadarMove - If either is true we execute the block and check

the Ladar Window. This checks this outputs if an obstace is

in the window. If it is, we execute a Ladar Action.

If we have a Ladar Action or if we were in a Ladar Move, we

continue the Ladar Move.

The fifth case execute when we have a Ladar Action. This case

determines the position of the obstacle and determines whether the

robot should turn left or right to avoid it. If there is a

larger window left of the obstacle we turn left. If there is

a larger window right we turn right.

The sixth case is only entered if we do not have a Ladar Move or Ladar

Action.. In this case we determine if we are on the correct bearing by

checking the current compass bearing against the desired bearing to the

next GPS point. We then turn toward the desired bearing if

necessary.

The sixth case executes a GPS move. This means that if there

are no obstacles in the way and we are on bearing move straight.

This final case pushes the speeds to the wheels.

Obstace Course

The first case of the obstacle course initializes all the boolan

variables to false.

The second case checks the ladar and the vision simultaneously.

It sets if there is an obstacle in the ladar view and ckecks

whether or not we need to backup based on ladar or vision.

Finally it also detemines the target angle based on the

vision system output.

Thie third case has a great deal of parallel cases. The first

shown here detemines if there is an obstacle in the window.

If there isn't then we used the camera target angle.

If there is an obstace in the window then we need to go through another

sequence statement. The first step of this sequence sets

windows based on the ladar target. The window tells us if

there is a space past the object on each respective side.

In this case it we execute if we have an available window on both the

left and right sides of the obstacle. In this case we use the

ladar target that corresponds most with the camera target,

This ensure that we will be moveing away from both lines and

objects if possible.

The third sub case takes the XOR of the left and right window boolean

variables. This means if we have one but not the other we

move toward the open window ignoring the camera target.

This final case says that if we do not have a window on either side

then we need to back up and look for a window again.

We then continue in the main sequence statement. we check if

we set either the Camera or Ladar Backup variables. If we

didn't then we turn based on the determined desired target from the

previous case. The turn is based on turning aggressivenes and

the desired target,

This is the case if we did return that we need to back up. In

this case we negate the speed in order to back up.

Finally, when we get to the final case of the sequence we push the

speeds to the motor.